WHY CHOOSE US

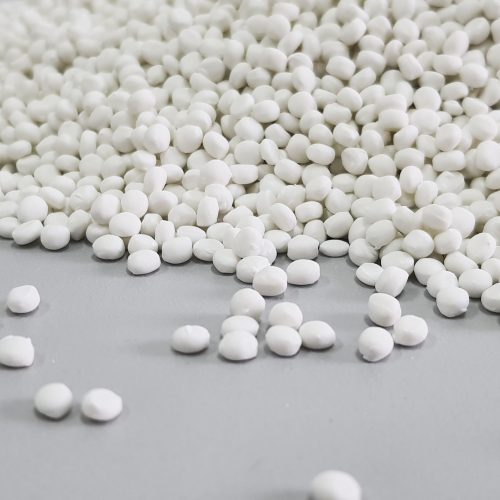

10+ Years of Experience The best supplier of Calcium Carbonate products

Established in 2011, we are proud of having many consecutive years as the best Calcium Carbonate supplier of Vietnam. ACBM Viet Nam Joint Stock Company is one of the leading companies in the areas of exploiting and exporting of CaCO3 products under brand “ACBM”

ABOUT US

ACBM VIET NAM JOINT STOCK COMPANY

In addition to the finest limestone quarries of Vietnam, we owns the most advanced technology imported from Germany and the latest laboratory equipments such as: Whiteness Analyzer MINOLTA CR-200/CR-210 made in Japan and Particle Diffraction MALVERN made in England. With the annual capacity of 200,000 MT, ACBM always guarantee a stable supply of Calcium Carbonate products at world-class quality to the market of India, Bangladesh, Japan, Korea, Sri Lanka,…

OUR CERTIFICATES

Bangladesh

India

Sri Lanka

China

Korea

Japan

Taiwan

Thailand

UAE

Ghana

Germany

Philipin

Indonesia

Spain

Singapore

Myanmar

Malaysia

Australia

Canada

Brazil

OUR PARTNERS

VIEW PHOTOGRAPH

With the annual capacity of 12,000 MT, ACBM always guarantee a stable supply of Calcium Carbonate products at world-class quality to the market of India, Bangladesh, Japan, Korea, Sri Lanka,…

NEWS

CONTACT US